Seni valdymo sistemos kiekvieną dieną sukelia vis didesnes problemas, nes gamintojai nebeprisiima jų palaikymo, o atsarginės dalys vis sunkiau rasti. Pagal 2023 metų tyrimą, atliktą ARC Advisory Group, beveik dvi trečiosios gamybos įmonių susiduria su sunkumais keičiant įrangos dalis, kai įrenginiai pasiekia 15 metų amžių. Modernizavimo komponentai šiai problemai sprendžia tiesiogiai, leisdami skirtingoms ryšių protokolams be problemų veikti kartu, kaip tarkim tarp Modbus RTU ir Ethernet/IP standartų, viską palikdami esamą įvesties/išvesties struktūrą. Jei nieko nepakeisime, šios pasenusios sistemos toliau kels netikėtas sustojimus, kels pavojus saugai ir tiesiogiai nesuderinsis su šiuolaikinėmis „išmaniosios gamybos“ technologijomis, kurios labai priklauso nuo interneto ryšio.

Kai originalios įrangos gamintojai nustoja teikti techninę pagalbą, daugelis pramonės įmonių kreipiasi į trečiųjų šalių aptarnavimo teikėjus arba bando patys kurti atvirkštinio inžinerijos sprendimus. Pagal 2023 m. duomenis iš Ponemon Institute tyrimų, šis metodas paprastai prideda apie 34 % prie vidutinio remonto laiko. Sekti naujas saugos reglamentus tampa kur kas sunkiau esant tokioms sąlygoms, ypač kai reikia atitikti reikalavimus, pateiktus ISO 13849-1 standarte. Geresnis alternatyva yra modernizuoti sistemas naudojant PLC emuliacijos įrenginius kartu su įvairiais protokolų tarpininkavimo sprendimais. Šie patobulinimai padeda išlaikyti palaikymą tarp skirtingų tiekėjų be nuostatos aukoti senesnių jaučiklių ir aktuatorių modelių, kurie vis dar veikia. Be to, jie sumažina priklausomybę nuo dalių, kurios jau nebėra lengvai prieinamos per tradicinius tiekimo kanalus.

| Iššūkis | % Įmonių paveiktų | Vidutinis išlaidų poveikis |

|---|---|---|

| Pasenusi valdymo technika | 68% | $1,2 mln./metus |

| Nepalaikoma sena programinė įranga | 52% | $840 tūkst./metus |

| Saugos standartų nesilaikymas | 41% | $620 tūkst./metus |

Šie sisteminiai pažeidžiamieji elementai pabrėžia reikalingumą modernizuoti. Ilginant įrenginių amžių ir mažinant eksploatacinius kaštus, valdymo komponentų modernizavimas paprastai grąžina investicijas per 18 mėnesių.

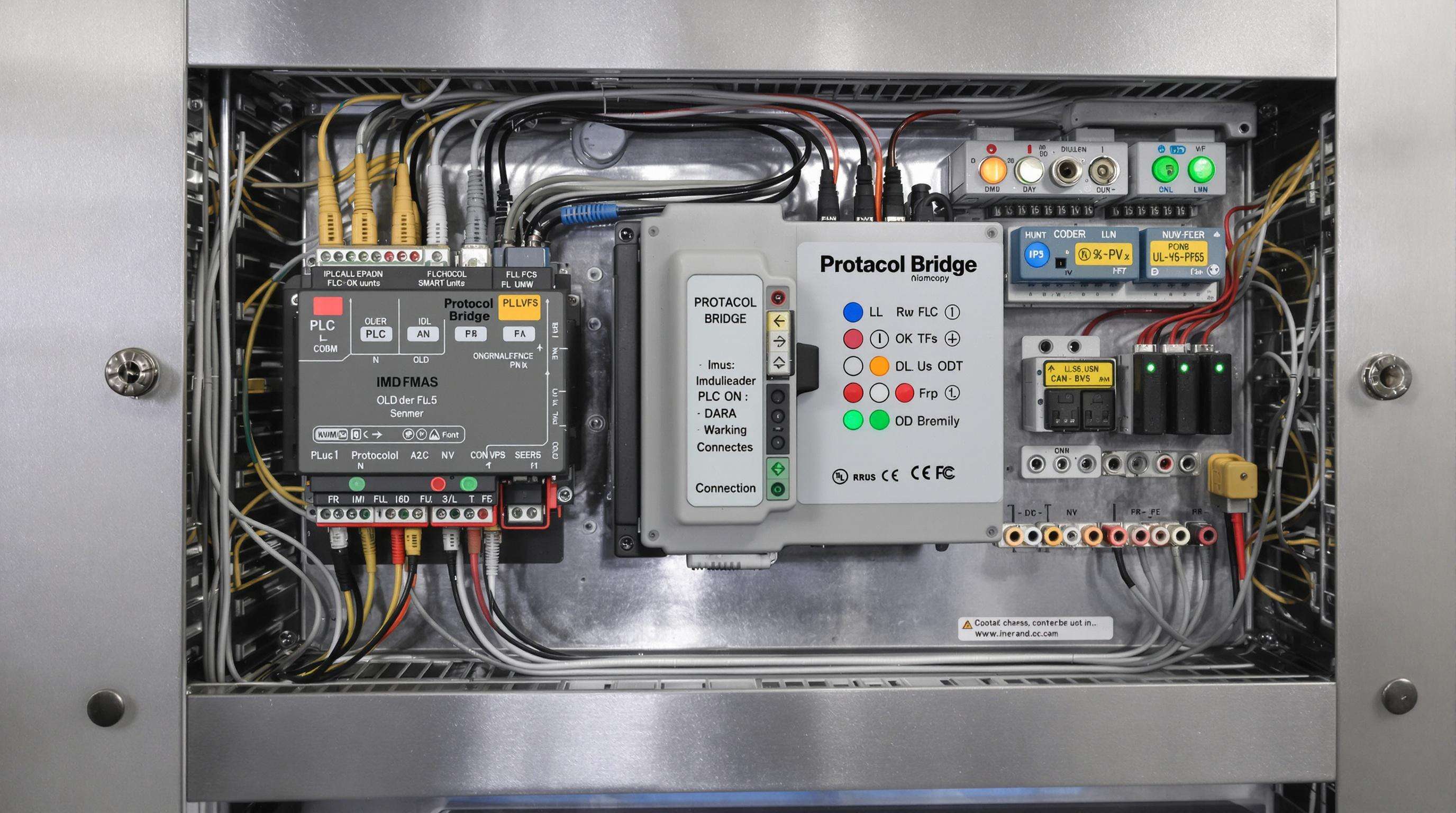

Protokolų tiltai padeda užpildyti spragą, kai naujesnei įrangai reikia bendrauti su senesnėmis valdymo sistemomis. Jie iš esmės verčia skirtingus protokolus, kad viskas veiktų kartu. Pavyzdžiui, jie gali konvertuoti Modbus RTU signalus į TCP/IP arba Ethernet/IP formatus, kuriuos supranta senesnės nuoseklios sistemos. Tai leidžia tiems moderniems įrenginiams iš tiesų komunikuoti su PLC, kurie gali būti 20 ar 30 metų senumo. Šie protokolų keitikliai veikia kaip vertėjai per pokalbį. Įmonės nurodo, kad rekonstravimo išlaidos sumažėja maždaug 40 %, o ne keičiant visas sistemas iš naujo. Be to, visa esama infrastruktūra lieka vietoje, o ne išmetama į šiukšles. jutikliai protokolų tiltai padeda užpildyti spragą, kai naujesnei įrangai reikia bendrauti su senesnėmis valdymo sistemomis. Jie iš esmės verčia skirtingus protokolus, kad viskas veiktų kartu. Pavyzdžiui, jie gali konvertuoti Modbus RTU signalus į TCP/IP arba Ethernet/IP formatus, kuriuos supranta senesnės nuoseklios sistemos. Tai leidžia tiems moderniems įrenginiams iš tiesų komunikuoti su PLC, kurie gali būti 20 ar 30 metų senumo. Šie protokolų keitikliai veikia kaip vertėjai per pokalbį. Įmonės nurodo, kad rekonstravimo išlaidos sumažėja maždaug 40 %, o ne keičiant visas sistemas iš naujo. Be to, visa esama infrastruktūra lieka vietoje, o ne išmetama į šiukšles.

Analoginių ir skaitmeninių I/O taškų išsaugojimas atnaujinant neleidžia pertraukti veiklos. Moduliniai terminalų blokai ir universalių I/O moduliai leidžia technikams:

Šiandien valdymo komponentai suderinti skirtingas sistemas dėl standartinių sąsajų, tokių kaip OPC UA ir MQTT protokolai. Šie kraštiniai šliuzo įrenginiai paima specialaus formato duomenis iš senų mašinų ir verčia juos į suprantamą formatą, kuris leidžia senam gamyklų įrenginiams bendrauti su naujai SCADA sistemomis realiu laiku. Pagal praeitų metų ARC Advisory Group paskelbtus tyrimus, įmonės, naudojančios tokią technologiją, sumažino integravimo išlaidas maždaug 32 procentais. Tuo pačiu metu, jos išlaikė beveik idealų prieigą prie duomenų – 99,5 procentų – visose skirtingų sistemų aplinkose. Toks našumas leidžia užtikrinti sklandžią veiklą be nuolatinių prastovų dėl atnaujinimų.

IoT galimybes turinčios valdymo komponentės keičia senesnės kartos mašinų analoginius signalus į skaitmeninius duomenų srautus, leidžiantis realiu laiku stebėti naudojant debesų technologijas pagrįstas valdymo pultus, nekeičiant originalios valdymo logikos. 2024 metų atvejo analizė parodė, kad metalo plovimo įmonė sumažino nenorimą prastovą 58 %, modernizuodama analoginius presus krašto skaičiavimo valdikliais.

Senos technikos modernizavimas prasideda nuo mechaninių relės pakeitimo į būsenos relę ir išmaniųjų daviklių montavimo hidrauliniuose ir pneumatinėse sistemose. Operatoriai nurodo 15–20 % našumo padidėjimą pridėjus būklės stebėjimo komponentus prie įrenginių, kurie buvo įdiegti dar 1960 metais, tokiais kaip vakuuminiai siurbliai ir kompresoriai.

Pramonės IoT modernizavimo rinka auga 42 % sudėtinės metinės augimo normos, kurią skatina paklausa dėl valdymo komponentų, leidžiančių skaitmeninę transformaciją be veikiančių turtinių objektų išmetimo. Priklausomybė yra didžiausia (73 %) pramonės šakose, reikalaujančiose nuolatinės veiklos, įskaitant farmacijos ir maisto perdirbimo pramonę.

Modulinės valdymo architektūros palaiko etapinį PLC keitimą per įstatomus stendus, suderinamus tiek su senais I/O moduliais, tiek su šiuolaikiniais procesoriais. Vienas svarbus automobilies pramonės tiekėjas per 18 mėnesių laikotarpio migravo senąją Siemens S5 sistemą (iš 1990-ųjų) į S7-1500 valdiklius naudodamas hibridines valdymo spintas, apribodamas gamybos sustojimus iki mažiau nei keturios valandos per fazę.

Palaipsniška modernizacija sujungia naujas Ethernet pagrįstas valdymo komponentas su išlaikytomis senesnėmis lauko magistralės įrangomis per protokolų tinklalapius. Toks „dvigubo steko“ metodas sumažina riziką, leidžiant įmonėms išlaikyti 85–90 % eksploatacinių galimybių per 12–24 mėnesių pereinamuosius laikotarpio. Skirtingų gamintojų suderinamumo testavimas lieka būtinas integruojant įvairaus kartos valdymo sistemas.

Kai gamintojai keičia tik konkrečias valdymo dalis, o ne visų sistemų komplektus, jie sutaupo tiek pinigų, tiek galvos skausmų. Keisti tik tai, kas reikia, iš tiesų yra protinga. Pvz., galima atnaujinti PLC procesorius, senose spintose įdiegti naujas HMI sąsajas arba pakeisti pasenusius tinklo įrenginius, kad sistemos veiktų ilgiau, nereikėtų visko išplėšti. Geriausia yra tai, kad įmonės nurodo apie 60 % išlaidų sutaupymą, kai pasirenkamas šis kelias, o ne visų pultų keitimas iš esmės. Šios tendencijos pastebimos remonto ataskaitose pastaruosius metus.

Strategiškai keičiant elektromechaninius komponentus sumažėja gamybos pertraukimai. Iš anksto pagamintos laidų lovos ir kištukinės gnybtų juostos leidžia technikams per keletą minučių pakeisti sugedusius relės ar pasenusius maitinimo šaltinius – 75 % greičiau nei tradicinis perdavimas. Pažangios įmonės standartizuoja komponentų pėdsakus kelioms kartoms, gerindamos suderinamumą tarp senųjų ir modernių valdymo komponentų.

Pagrindinėje diskusijos vietoje yra iššūkis, kuris susijęs su būtinybe sverti galimą augimo potencialą ir tuoj pat atsirandančius finansinius apribojimus. Pilni sistemos pakeitimai turi privalumų, tokių kaip kraštinių skaičiavimo technologijų integruotė, tačiau pagal 2024 metų pramonės tyrimus, maždaug aštuoni iš dešimt gamyklų vadovų vis dar renkasi palaipsniui tobulinimus, kai finansai yra riboti. Atskirų komponentų modernizavimas sumažina problemas, kurios gali kilti per programinės įrangos perkėlimo procesus, nors tai reikalauja kruopštaus tikrinimo, siekiant užtikrinti, kad visos dalys sėkmingai veiktų kartu, kadangi įrenginiai skirtingomis kartomis yra šalia vienas kito įdiegti įrenginiuose šiandien.

Karšto keitimo valdymo moduliai leidžia keisti I/O korteles, ryšių šliuzus ir energijos tiekimo vienetus be sistemos išjungimo. Puslaidininkų gamintojas sumažino metinį prastovą 420 valandų naudodamas modulinius komponentus su automatinio atsarginio kelio funkcija, pasiekdamas 99,98 % operacinių galimybių modernizuodamas skydelius etapais.

Keičiant seną pramonės įrangą naujais valdymo komponentais galima iš karto padidinti našumą. Kai įmonės modernizuoja savo sistemas, jos paprastai pasiekia nuo 12 iki net 18 procentų mažesį energijos suvartojimą dėl pagerintų variklių valdymo ir protingesnio energijos valdymo. Tuo pačiu pridėjus daviklius ir automatizavimą padidėja gamybos našumas tarp 15 ir 22 procentų. Daugelis įmonių pastebi, kad šie investicijai pradeda atsipirkti gana greitai. Pavyzdžiui, viena pakuotės įmonė praėjusį metą įdiegė kai kuriuos protingus relės kartu su kintamos dažnio variklio valdikliais. Tai sumažino jų metinį elektros suvartojimą 410 milijonų vatvalandžių, kuris žymiai paveikė galutinį rezultatą.

Dėka modulinės PLC sistemos ir lanksčiųjų įvesties/išvesties modulių, kuriuos galima konfigūruoti per programinę įrangą, sena mašinų įranga įgyja naujo gyvenimo. Pagal 2024 metų pradžios pramonės duomenis, maždaug trys ketvirtadaliai gamyklų, atnaujinusių valdymo sistemas, sumažino perkūrimo laiką nuo 60 iki 80 procentų. Tai reiškia, kad gamybos linijos gali būti perjungiamos daug greičiau, nereikia keisti jokių fizinės įrangos. Šį metodą taip pat ryžtingai įsisavino automobilių pramonė. Dabar daugelyje gamyklų naudojami presai, kurie veikia jau dešimtmečius, tačiau gali apdoroti visiškai skirtingus EV baterijų dizainus, tiesiog atnaujinus programinę įrangą programuojamuose loginiuose valdikliuose. Nebereikia brangių techninės įrangos modernizavimų.

Nepaisant tam tikrų integravimo sunkumų, atnaujinant atskirus valdymo komponentus faktiškai gaunami kur kas geresni rezultatai nei keičiant visas sistemas. Naujausios įmonių įrenginių priežiūros tyrimų duomenys rodo, kad atnaujinus atskirus komponentus galima gauti nuo 300 iki 400 procentų investicijų grąžą, atsižvelgiant į visą sutaupytą energijos kainą, išvengtą gamybos stabdymą ir ilgesnį esamų objektų naudojimą. Turbūt todėl apie dvi trečiosios gamintojų jau pradėjo dėmesį skirti šiems mažesniems mastelio atnaujinimams, o ne visų sistemų kapitaliniam atnaujinimui, netgi objektuose, kurių infrastruktūra jau senesnė nei ketvirtį šimtmečio.

Senųjų mašinų modernizavimas reiškia senesnių pramonės sistemų atnaujinimą naujais valdymo komponentais, nekeičiant viso įrenginio, padedant pagerinti suderinamumą ir efektyvumą.

Modernizavimas yra svarbus, nes jis pašalina pasenusių technologijų problemas, sumažina priežiūros sunkumus ir užtikrina atitikimą saugos standartams, todėl ilginamas senos įrangos tarnavimo laikas ir pagerinamas jos veiklos efektyvumas.

Protokolų tiltai veikia kaip vertėjai tarp skirtingų ryšių standartų, leidžiant naujoms įrenginiams bendrauti su senesnėmis valdymo sistemomis, taigi užpildant skirtumus tarp kartų.

Modernizavimas gali sukelti reikšmingus efektyvumo padidėjimus, sumažinti energijos suvartojimą, pagerinti eksploatacinius rodiklius ir padidinti investicijų grąžą, pratęsiant esamų įrenginių naudojimo laiką.

Hot News

Hot News2024-09-20

2024-09-20

2024-09-20

Autorių teisės © TECKON ELECTRIC (SHANGHAI) CO., LTD Privacy policy