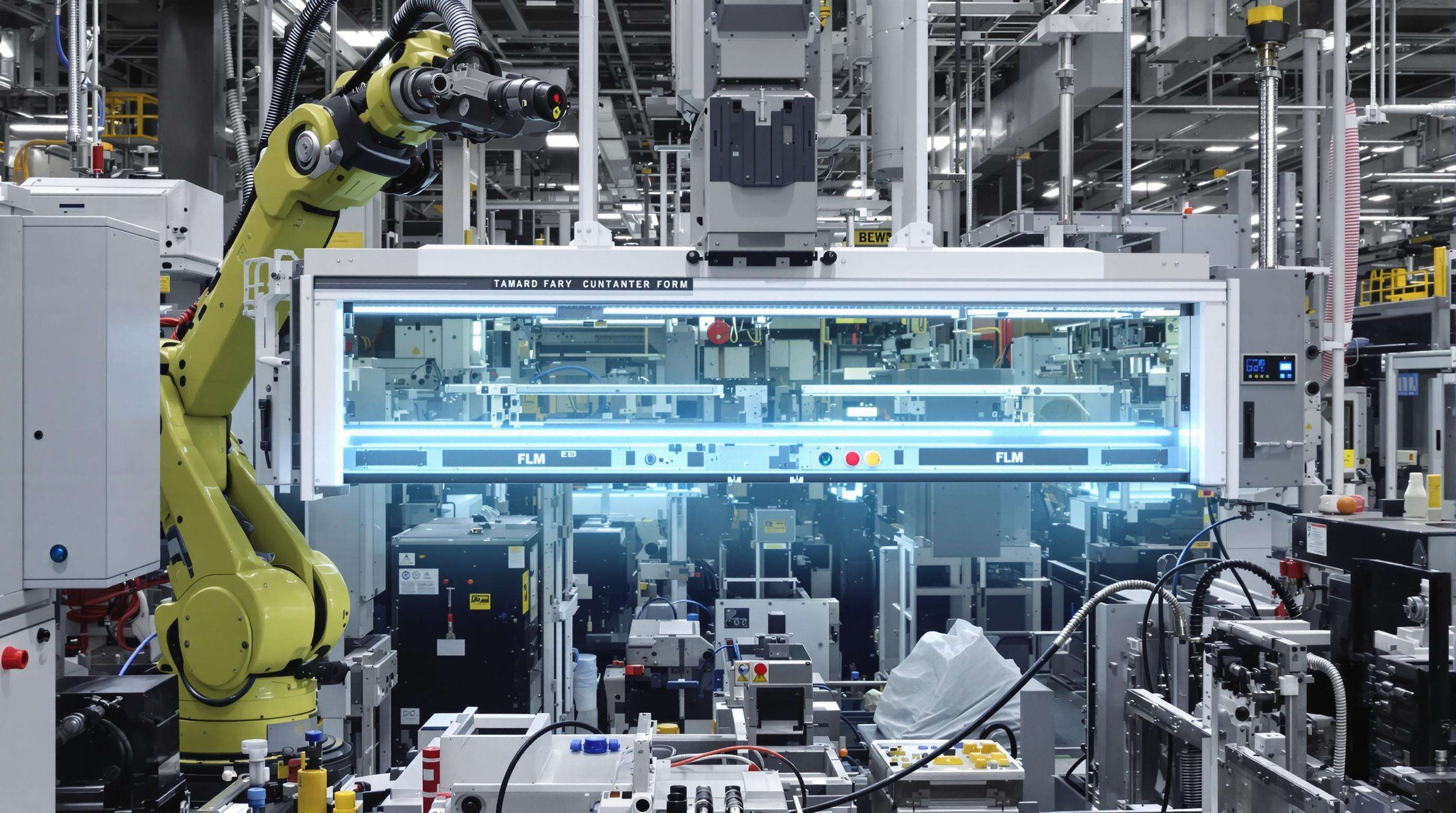

Jaunākie kompaktie drošības gaismas aizkari instalācijas vietās ietaupa līdz 30% salīdzinājumā ar vecākiem optiskajiem aizsardzības sistēmu modeļiem, saglabājot to pašu drošības standartu līmeni saskaņā ar 2024. gada Robotic Safety Guidelines. Šīs ierīces ir ļoti plānas — resnākas par 40 mm —, tādēļ tās var uzstādīt tieši uz robotu rokām vai ievietot šaurās vietās pie ražošanas līnijām, nebojājot esošās darbības. Patiesi ievērojami ir to modulārā konfigurācija, kas ļauj izveidot vairākus drošības līmeņus, kas pielāgoti sarežģītām mašīnu izvietojuma shēmām. Šī funkcija ir īpaši svarīga tādās vietās kā automatizētie noliktavas un ļoti tīrās pusvadītāju ražošanas telpās. Runa ir par telpām, kur katrs kvadrātmetrs uzņēmumiem maksā vairāk nekā 740 ASV dolārus gadā, kā norādīts Ponomēna pētījumā pagājušajā gadā.

2024. gada analīzē par automašīnu montāžas līnijām konstatēts, ka kompaktie gaisīgie aizkari aizņem par 58 % mazāk sānu vietas nekā tradicionālie modeļi. Tas ļauj ciešāk izvietot mašīnas, neizmantojot pārklājošās drošības zonas, palielinot ražošanas blīvumu par 22 % automatizētajās metināšanas šūnās. Zemāk esošajā tabulā redzami vietas ietaupījumi galvenajās nozarēs:

| Nopelumi | Tradicionālais izmērs (m²) | Kompaktais modelis (m²) | Ietaupītā vieta |

|---|---|---|---|

| Autoindustrija | 1.8 | 0.7 | 61% |

| Elektronika | 1.2 | 0.5 | 58% |

| Farmaceitiskie preparāti | 0.9 | 0.3 | 67% |

Pēdējā laikā uzlabota elkošo PCB ražošana ļauj tiem maziem drošības gaisīgajiem aizkariem faktiski saliekties ap stūriem uzstādīšanas laikā, padarot tos daudz vieglāk uzstādāmus uz tiem sarežģītajiem līkumainajiem transportieriem, ko bieži sastop rūpnīcās. Vairs nav nepieciešami lielie metāla skavas, kas aizņem vietu un parasti pievieno kaut kur no 120 līdz 150 milimetriem papildu platuma mašīnām. Jaunākā paaudze mazie izturīgie sensori rated IP69K izmērā tikai 6 ar 6 milimetriem. Šie mazie ierīces joprojām atbilst Type 4 drošības standartiem, taču aizņem daudz mazāk vietas salīdzinājumā ar 2020. gadā pieejamo. Saskaņā ar pērn publicētiem pētījumiem ar nosaukumu Material Flexibility Studies, šie jaunie mikrosensori iekļauj visu šo aizsardzību korpusos, kas aptuveni par trīs ceturtdaļām ir mazāki nekā iepriekšējie modeļi.

Aziātu pusvadītāju uzņēmums izdevās atbrīvot aptuveni 34% vērtīgās grīdas platības savā 300 mm disku fabrikā, nomainot 58 vecos gaismas aizkara sistēmas pret jaunām, kompaktākām versijām. Ar šo papildu telpu parādījās iespēja uzstādīt 11 papildu apstrādes vienības tajā pašā tīrās telpas platībā, nekompromitējot prasītos SIL 3/PLe drošības standartus. Pārveidotie infrasarkanā starojuma masīvi samazināja patērētās jaudas lielumu katrā drošības zonā par aptuveni 41 procentu. Tas nozīmē, ka vien tikai vienā ražošanas līnijā katru gadu tiek ietaupīti apmēram 62 miljoni vatu stundu. Diezgan iespaidīgi, ņemot vērā cik šauri ir peļņas rādītāji šobrīd mikroshēmu ražošanā.

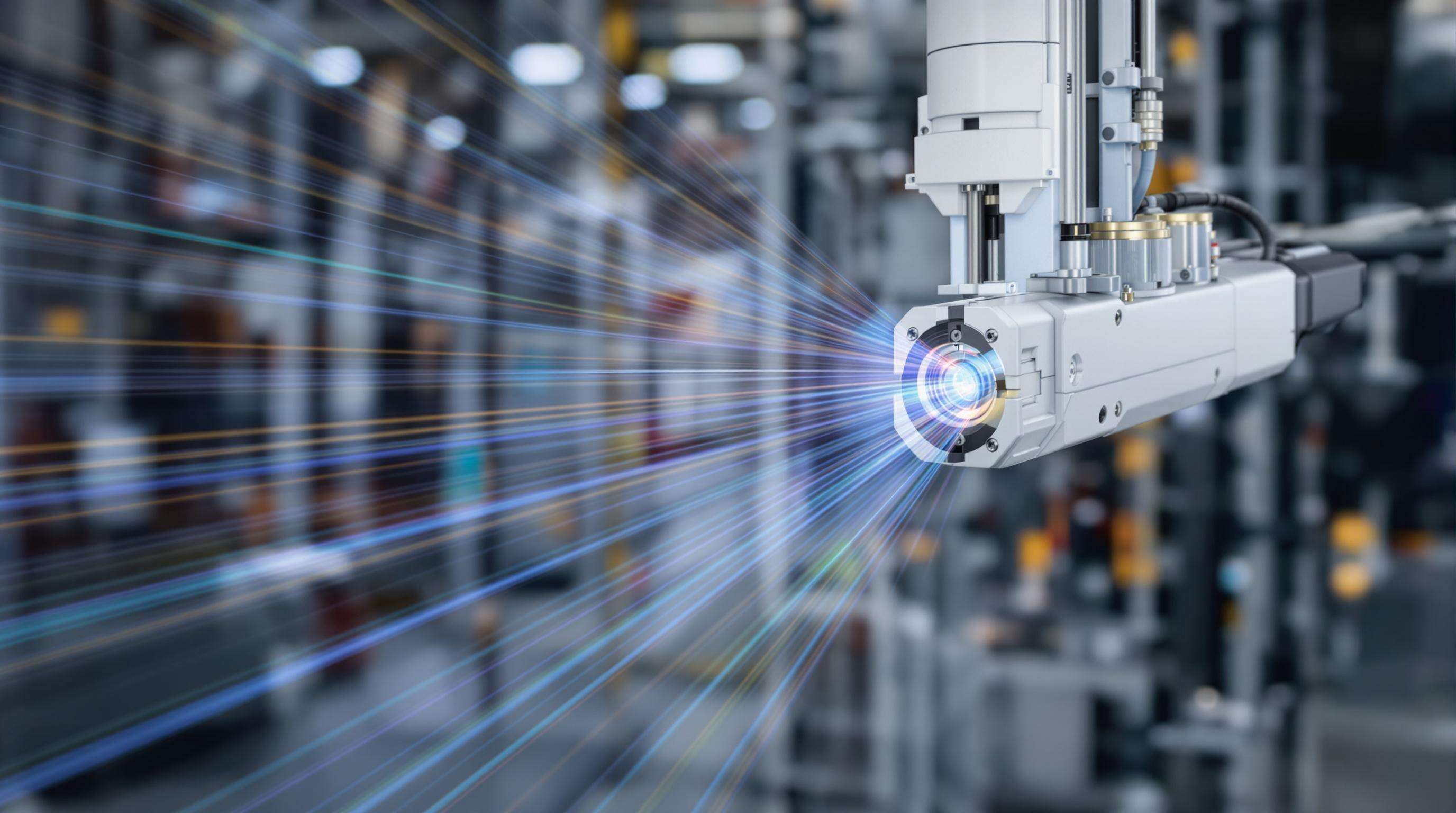

Mūsdienu kompaktie drošības gaismas aizkari tagad ir ar 14 mm staru attālumu, kas spēj uztvert kaut ko tik sīku kā cilvēka pirksta gals. Saskaņā ar HSEBlog rakstu 2023. gadā tas patiešām ir apmēram par 60 procentiem labāks nekā bija pieejams pirms dažiem gadiem. Šiem ierīcēm ir iebūvēti adaptīvas jutības iestatījumi, kas automātiski pielāgojas atkarībā no to apkārtnē esošajiem apstākļiem, piemēram, vibrācijām vai putekļu uzkrāšanām. Tas nozīmē, ka sistēma joprojām reaģē 2 milisekundēs vai ātrāk, pat tad, ja to izmanto ļoti delikātai darbībai, piemēram, pusvadītāju plāksnīšu pārvietošanai, kur laiks ir ļoti svarīgs. Ražotāji šo ierīču dēļ vērtē to, ka tās nodrošina drošību uzņēmuma ražošanas līnijās, neizraisot procesu aizkavēšanos.

Kaut Tipa 2 gaismas aizkari (PL c\/SIL 1) der vienkāršai iebrukuma noteikšanai, Tipa 4 sistēmas (PL e\/SIL 3) ir izplatītas augsta riska vidē pateicoties trim galvenajām uzlabojumu kategorijām:

| Iezīme | Tips 2 | Tips 4 |

|---|---|---|

| Kļūdu izturība | Atsevišķas kļūdas noteikšana | Divkanālu uzraudzība |

| Atbildes laiks | 15–20 ms | ≤ 8 ms |

| OSHA Atbilstības joma | 32% no lietošanas gadījumiem | 89% no industriālajiem bīstamajiem faktoriem |

Saskaņā ar 2024. gada industriālās drošības ziņojumu, automašīnu robotikā 4. tipa pieņemšana palielinājās par 42% salīdzinājumā ar iepriekšējo gadu, ko nodrošināja augstāka uzticamība un plašāks bīstamo faktoru pārklājums.

Nākamās paaudzes modeļi patērē par 37% mazāk elektroenerģijas nekā iepriekšējās versijas un to korpusa dziļums ir tikai 24 mm — ideāli piemēroti iekārtām ar ierobežotu vietu, neizmainot esošo ražošanas izkārtojumu. Šie sasniegumi atbalsta:

Galvenais kompakti izstrādātu sistēmu ierobežojums — samazināts detekcijas diapazons — tiek novērsts, izmantojot mākslīgā intelekta algoritmus, kas kompensē vides traucējumus. Saskaņā ar 2023. gada Fraunhofer institūta pētījumu, pareizi konfigurētas kompaktas iekārtas sasniedz 99,998 % bojājumu noteikšanas līmeni, nodrošinot tādu pašu uzticamību kā lielākas sistēmas, bet izmantojot par 28 % mazāk grīdas platības.

Drošības gaismas aizkarai, kas aizņem minimālu vietu, kļuvuši par būtiskām moderno ražošanas iekārtu sastāvdaļām, īpaši Industry 4.0 vidē, kur mašīnām ir nepieciešama gan aizsardzība, gan maksimāla ražīgums. Šīs kompaktās sistēmas tiek ražotas ar profiliem pat līdz 25 mm platumā un piedāvā pielāgojamus staru iestatījumus, kas nodrošina saderību ar lielāko daļu ražošanas iekārtām PLC sistēmas un bez problēmām integrējoties IoT tīklos nepārtrauktai iekārtu izsekošanai. Pusvadītāju nozarē ir konstatēti taustāmi šīs tehnoloģijas priekšmeti, ar uzņēmumiem ziņojot par apmēram 18% mazāk laika, kas zaudēts drošības saistītu problēmu dēļ pēc šo sistēmu uzstādīšanas. Turklāt to kompaktā izmēra dēļ rūpnīcām ir iespēja saglabāt efektīvu izkārtojumu pat tad, kad ražošanas līnijas paplašinās un attīstās laika gaitā.

Modulāri kompakti gaisma aizkari kļūst par būtiskiem drošības līdzekļiem automašīnu metināšanas kamerās, kur sadarbības roboti strādā tikai 500 mm attālumā no cilvēku operatoriem. Šie sistēmu atbilst stingrām ISO 13849 PL d drošības standartiem, kas ir ļoti svarīgi atbilstībai. Arī pārtikas pārstrādes iekārtām IP69K klase nozīmē, ka šie gaisma aizkari izturēs smagas augstspiediena mazgāšanas procedūras, nezaudējot funkcionālumu. Saskaņā ar neseno nozares ziņojumu par 2024. gadu, ražošanas uzņēmumi, kas pārgāja uz šiem modernajiem drošības risinājumiem, konstatēja, ka kameru pārbūves laiks samazinājās par apmēram 23% salīdzinājumā ar vecākām barjeru sistēmām. Tāda veida efektivitātes pieaugums dod reālu atšķirību, kad ražošanas grafiki kļūst sarežģīti.

Ultraplānas drošības gaismas aizkaru sistēmas, kuras var būt tikai 17 mm platas, atbalsta pārkonfigurējamus darbavietas, kas atbilst modulāras inteligentas ražošanas principiem. Tekstilražotāji ziņoja par 40 % ātrāku produktu nomainīšanu pēc stingru gaismas ekrānu aizvietošanas ar kompaktām uz tērauda riteņu montētām ierīcēm, kuras var viegli pārvietot gar ražošanas līnijām.

Mūsdienīgas kompaktas gaismas aizkaru sistēmas ievērojami maina augstas ātrdarbības ražošanas vidi, apturot aptuveni 73% no šiem nepatīkamajiem negaidītajiem ražošanas pārtraukumiem, pateicoties milimetru viļņu detekcijas tehnoloģijai un reakcijas laikam, kas ir mazāks par 2 milisekundēm, kā norādīts Ponemon ziņojumā 2023. gadā. Šīs sistēmas ļoti reti izslēdzas bez iemesla, kas rūpniecībā automašīnu montāžas līnijās ir samazinājis materiālu atlikumu gandrīz par 30% saskaņā ar pagājušā gada Rūpnieciskās ilgtspējas ziņojumu. Šo ierīču lielo vērtību nosaka to kompaktais izmērs, kas ļauj rūpniecības vadītājiem ātri pielāgot telpu izkārtojumu, nezaudējot darba ņēmēju drošību – kas ir ļoti svarīgi, kad uzņēmumiem jānodrošina, lai aprīkojuma darbnespējas laiks būtu zem kritiskā 0,5% sliekšņa, ko prasa liums ražošanas standarti mūsdienās.

Šo gaismas aizkaru kompaktā dizaina dēļ materiālu patēriņš tiek samazināts par aptuveni 34%, vienlaikus samazinot enerģijas patēriņu par apmēram 18% katram uzstādītajam drošības sistēmas veidam. Vēl viena priekšrocība ir to modulārā konstrukcija, kas ļauj uzņēmumiem mainīt atsevišķas detaļas, nevis aizvietot visu sistēmu. Šāds pieejas veids ļauj novērst aptuveni 2,1 tonnas elektronisko atkritumu nokļūšanu atkritumu poligonos katru gadu vienai ražošanas līnijai, liecina 2023. gada MIT pētījums par ciklisku ražošanu. Turklāt, tā kā šīs sistēmas lieliski darbojas ar spriegumu no 14 līdz 24 voltiem līdzstrāvā, tās labi iederas atjaunojamo energoresursu iekārtās. Tas nozīmē, ka rūpnīcas var mazāk paļauties uz standarta 110 voltu maiņstrāvas elektrotīklu, kas kļūst aizvien svarīgāk, kad uzņēmumi cenšas padarīt savu darbību videi draudzīgāku.

Neatkarīgu ekspertīžu rezultāti par cikla ilgumu atklāj, ka kompaktie drošības gaismas aizkari 7 gadu laikā nodrošina par 40% zemākas īpašumizmaksas salīdzinājumā ar tradicionāliem modeļiem. Galvenie faktori ir:

Īso drošības gaismas sistēmu tirgus faktiski ir diezgan daudz pieaudzis, pēdējos datos no 2024. gada Industrial Automation Survey liecina, ka tas ir pieaudzis apmēram par 72 procentiem kopš 2020. gada. Vecās rūpnīcas, kuras tiek modernizētas, un jaunās ražošanas vietas, kas vēlējušās labāk izmantot grīdas platību, ir sākušas izvēlēties šīs plānās drošības aizkarus, nevis lielās un masīvās aizkaras, kuras agrāk redzējām visur. Praksē tas nozīmē, ka mašīnas šodien aizņem ievērojami mazāk vietas, apmēram par 15 līdz pat 40 procentiem mazāk atkarībā no konkrētās iekārtas konfigurācijas. Tas ir ļoti svarīgi, jo īpaši tādās vietās kā automašīnu detaļu ražošanā, kur katrs kvadrātcollas ir svarīgs, ja vēlas palielināt ražošanas apjomus, neceļoties uz lielākām ēkām.

Augstas tīrības pusvadītāju ražošanā kompaktie gaismas aizkari pasargā disku apstrādes robotus ISO klases 1 tīrās telpās, kur viens vienīgs piesārņojuma gadījums var izmaksāt no 500 000 līdz 2 miljoniem USD (SEMI 2023). Lideru ražotāji ziņo par 22% ātrāku ražošanas ciklu pēc pāriešanas uz kompaktajām sistēmām, piebilstot šo ieguvumu datorizētām mehāniskām traucēm un vienkāršotai pārkonfigurācijai.

Tirgus pētījumi liecina, ka telpu optimizēto drošības risinājumu nozare nākamajā desmitgadē attīstīsies diezgan strauji, pieaugot apmēram par 14 procentiem katru gadu līdz 2030. gadam. Šo izaugsmi lielā mērā veicina palielinātas izmaksas par gudro rūpnīcu sistēmām un zaļās enerģijas projektu visā pasaulē. Skatoties uz to, kas notiek konkrēti Ziemeļamerikā, ražotāji atklāj, ka šodienām viņiem ir nepieciešama mazāka drošības iekārta. Apmēram divas trešdaļas no visām nesenajām automatizācijas uzlabojumiem patiešām prasa komponentus, kas nav lielāki par 50 milimetriem platus — kaut ko, ar ko tradicionālās gaismas aizkaru sistēmas vienkārši nevar tikt galā. Šķiet, ka pieprasījums arī nekavējas. Jaunās lietojumprogrammas, kas rodas tādās jomās kā akumulatoru paketju ražošana un mikroelektronisko detaļu ražošana, liecina par turpmāku interesi par kompaktajām drošības tehnoloģijām, neskatoties uz to, ka šī joma jau ir pastāvējusi vairākus gadus.

Kompaktie drošības gaismas aizkaru ierīces ir sarežģītas drošības ierīces, ko izmanto rūpnieciskās vides, kur tās samazina uzstādīšanas vietu, saglabājot augstus drošības standartus.

Šie gaismas aizkari ir izstrādāti, lai būtu tievāki un modulārāki, ļaujot iekļauties šaurās telpās un veicināt mašīnas izmēru samazināšanu, saglabājot drošību.

Automobiļu, elektronikas un farmācijas nozarēm ir vislielākais ieguvums, jo ir nepieciešams maksimāli izmantot ražošanas telpas.

Tie var bez problēmām pieslēgties IoT tīkliem un PLC sistēmām, nodrošinot reāllaika izsekošanu un efektīvu drošības pārvaldību inteligentās ražošanas iestādēs.

Šīs ierīces samazina materiālu patēriņu un enerģijas patēriņu, bet to modulārā konstrukcija palīdz novērst nevajadzīgu elektronisko atkritumu.

Hot News

Hot News2024-09-20

2024-09-20

2024-09-20

Autortiesības © TECKON ELECTRIC (SHANGHAI) CO., LTD Privacy policy